Our man Clayton has already started building this Takom brand AMX-13/75 kit. Today he shows us how to build the kit in the easiest way possible so you can get it painted and on the competition tables ASAP…

In Boxed: AMX13/75

From: Takom

Kit# 2036

1/35th scale

Plastic sprues, photo etched material

Decals for 6 variants inside

Available from Takom’s Distributors Worldwide.

Part I of this review - the In-Box section is here at this link

Today PtII sees Clayton get building his kit.

Shortly after the end of the Second World War, the French felt there was a need for a lightweight, air portable tank that was both fast and offered a big punch. Conflict in Indochina and Algeria saw production fast-tracked and in 1946, the AMX 13/75 was born.

In order to keep the size and the weight of this new tank down, the designers needed to adopt a new way of thinking. Rather than housing a big gun that traversed in a rotating turret, they came up with the idea of the oscillating turret. Essentially this meant that in order to manoeuvre the gun up and down, the whole turret would move rather than just the gun itself.

The other benefit of this design was the ability to pair it with an auto-loading system. This not only could increase the rate of fire of the vehicle but also, would make the Loaders role in the tank redundant, hence decreasing the number of men to operate the vehicle and decreasing the service weight.

The 75mm gun was actually a modified design from the weapon found in the German Panther. It was mounted high in order to provide good vision in a dug in position, whilst the low profile chassis meant the tank was rarely exposed. The compact design of the vehicle even had a bearing on the recruitment policy of the French army. The maximum height of a tanker in the AMX was only 1700mm tall.

The AMX would go on to receive upgrades and larger weaponry, as the 75mm would prove to lack a little punch on the battlefield. The AMX was exported to 25 Nations around the World.

On to the build.

The initial steps of the build see the running gear and the main assembly of the tank come together. I decided to not fix the running gear in place so it could be removed during the painting phase.

The fit was very good and trouble free.

Drivers hatches and Photo etch grills are now fitted off to the top of the model. The mesh in the PE is very fine and can tend to clog up with supa-glue if you aren’t careful. Use glue sparingly.

The next steps see the side guards fixed to the structure. Given the multiple versions of this AMX available, some minor plastic surgery is required to ensure we will end up with the correct details for your version. The instructions are clear and easy to follow. I made the decision to hold off attaching the rails until the tracks had been made. I wanted to make sure I would have no access issues with the guards on.

After clipping all of the individual links off the sprues, I went about loosely joining them. Most of the pieces came off cleanly, but one or two needed to be lightly sanded in order to nest nicely in with the other links.I began by connecting them into smaller lengths and then bringing them together to the length I wanted. A small drop of Revel Contacta cement in each joint was all that was needed to hold the tracks together.

After about 5 minutes, the glue had set enough to allow me to bend the tracks around the running gear and simulate a sag. The instructions called out for 82 links per side, but I found 79 to 80 was a better number fit.

Because the running gear had not been glued, I could now remove the tracks and wheels, ready for paint.

The headlight assemblies gave me a bit of grief. I found the instructions to be a little confusing and ended up making a mess of them. I decided to fit the moulded plastic parts and would come back later and fit off the nice little PE parts.

In this picture you see the exhaust, toolboxes and side guards have now been fitted.

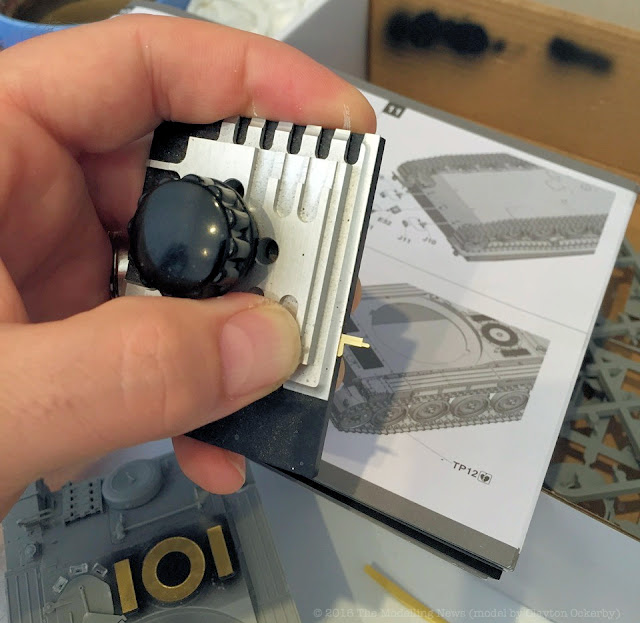

Some fine PE parts are now required for the rear of the vehicle. A bending tool is required at this point. The parts bent cleanly and were easy enough to manage.

Step 14 sees you having to make a choice. You can either build the standard version or the IDF version. Whilst I am sure the IDF version will be the main reason most will pick up this boxing of the kit, I have decided to produce the Standard version. Again, some minor plastic surgery and some holes to make way for later steps.

Details are then added to the turret. There are some very fine pieces to clip off the sprues, so care must be taken to avoid breaking them. The fine detail in this model is really starting to present itself.

I did, however, find the way the turret was connected to the turret ring to be a little awkward in its design and took more than a little patience to get it to a point where I was happy.

The barrel was supplied in two equal halves and went together very nicely. Still more detail is added to the turret and the body of the tank.

I have modelled the stabilising bracket for the barrel in the down position, as this model will be posed in action. There were a number of fine parts here also, so care must be taken when handling them. Again, the instructions were a little vague for my liking, so I am only guessing that the parts are all sitting correctly.

To add some interest to the model, I added some straps to the rear storage tub. The lead foil was cut into thin strips and fixed in place with supa-glue. This was done in numerous small pieces to give the illusion that the straps were being fed through the brackets. I have to confess; I was inspired to add the straps after seeing Mig’s IDF version of this tank. The straps really brought the model to life, and I had to ‘borrow’ the idea for mine.

The headlight grills are now fixed in place. The actual lights will go in after I have painted the model so I can keep the lenses clean through the painting process.

The finished model –

Finally, the model was primed with Alclad Grey Primer and Microfiller, ready to get the first hit of paint in the next few days.

I remember winning the Heller version of this tank as a prize when I was a kid and being horrified at this odd looking tank. ‘Who would ever want to build this?’ I remember thinking…. But after building this new release from Takom, and learning a little more about this interesting little tank, I find myself asking..’who wouldn’t want to build this!’

In terms of a model, this is of a very high standard, and I enjoyed watching this one come together. Whilst I have been happy with the level of detail in Takom releases in the past, this one seems to have stepped it up a little in the finer details. It did make the model a little more fragile and more difficult to handle than I have been used to, but that is one of the things I liked about it.

The moulding quality and fit are all very good, and the inclusion of a detailed photo etch set ensures the model has those little finer details that add so much to the finished model. There are a couple of steps in the instructions that I felt could have been detailed a little more clearly, but you will work your way through those. Just take your time to work through it.

With three different versions of this tank available, there is now doubt that Takom has come up with another winner. It will be interesting to see how the Tamiya release stacks up against this one, but for my money, I would find it had to go past the detail and the buildability for this model.

I do sound a little like a broken record, but what a great time to be in this hobby. Congratulations again to Takom for another fantastic model of a truly interesting tank.

Stay tuned for part two, where I will paint and weather this one up in the markings of the Venezuelan Army.

This kit is now available from Takom’s Distributors Worldwide. Thanks to them for sending this kit to build & review.