Kittyhawk has brought its 48th scale Su-35 “Flanker E” to the market, and our man Bruce is building his at apace - he is up to his guts in plastic right now, see just how it is coming together in his build guide...

Construction Guide: Sukhoi Su-35 "Flanker-E"

From: Kittyhawk

1/48th scale

Product Number# KH80142

Product Link on the Kittyhawk Site

Price: £49.49 on the E-Models Website

Today: Kittyhawk's 48th scale Su-35 "Flanker E" Build Guide Pt. I:

I decided to start with the wings for no other reason than it was the first sprue that I picked up! Kittyhawk plastic is still, in my opinion too soft, although the engraved detail is quite sharp, some parts show stress marks and swirls.

The lower wing joins the upper half in from the tip which is moulded full thickness to the upper half. A small blob of Blu-Tac was used as a spacer to ensure I had a clean join with no step. Using Blu-Tac allows me to squash it down to the right height rather than trying to find the correct thickness plastic card.

Unfortunately, the seams needed to be eradicated as there is no panel line here on the real jet.

The rivets were reinstated with a 1.0mm Riveter tool which gives you the correct spacing as per the kit rivets. The undersides of the slats have a sink mark which needs to be filled. Taping them to the wing shows a good fit in both the raised or lowered position, although KH have really designed them to be fitted in the flush position as the glueing surfaces are a little tenuous if you keep them lowered

The flap actuator arms push snugly into holes in the trailing edge. If glueing these in the flush position, you will need to cut the angled tabs off.

Again, meandering through the instructions, I decided to construct the wheel wells. The nose well is built up from two halves which will mean the centre seam needs eradicating. The main wells are assembled from separate parts to build up an open top box with the lower fuselage half forming the roof.

Out of the box, they look busy enough, of course, they can be further detailed if you wish. However, I would advise painting them at this stage, otherwise, you will never get into them to paint the details once the intakes are in place. I used a Medium sea grey as called out in the instructions with details picked out in Vallejo colours. A black wash was then applied.

At this stage I thought I might actually follow the order the stages are laid out in the instructions, so went back to Step One to tackle the cockpit.

The K36 ejection seat is made up of several parts, all of which go together to make a nicely detailed seat. They even offer a choice of seat cushions or the protective cover

The assembled seat was painted with Vallejo colours. I would echo Gary’s comments from his fitter review that KH’s instructions do not adequately illustrate how the belts should sit, also, I echo Gary’s comments that the kit seat is entirely adequate and an aftermarket seat would not add a lot more.

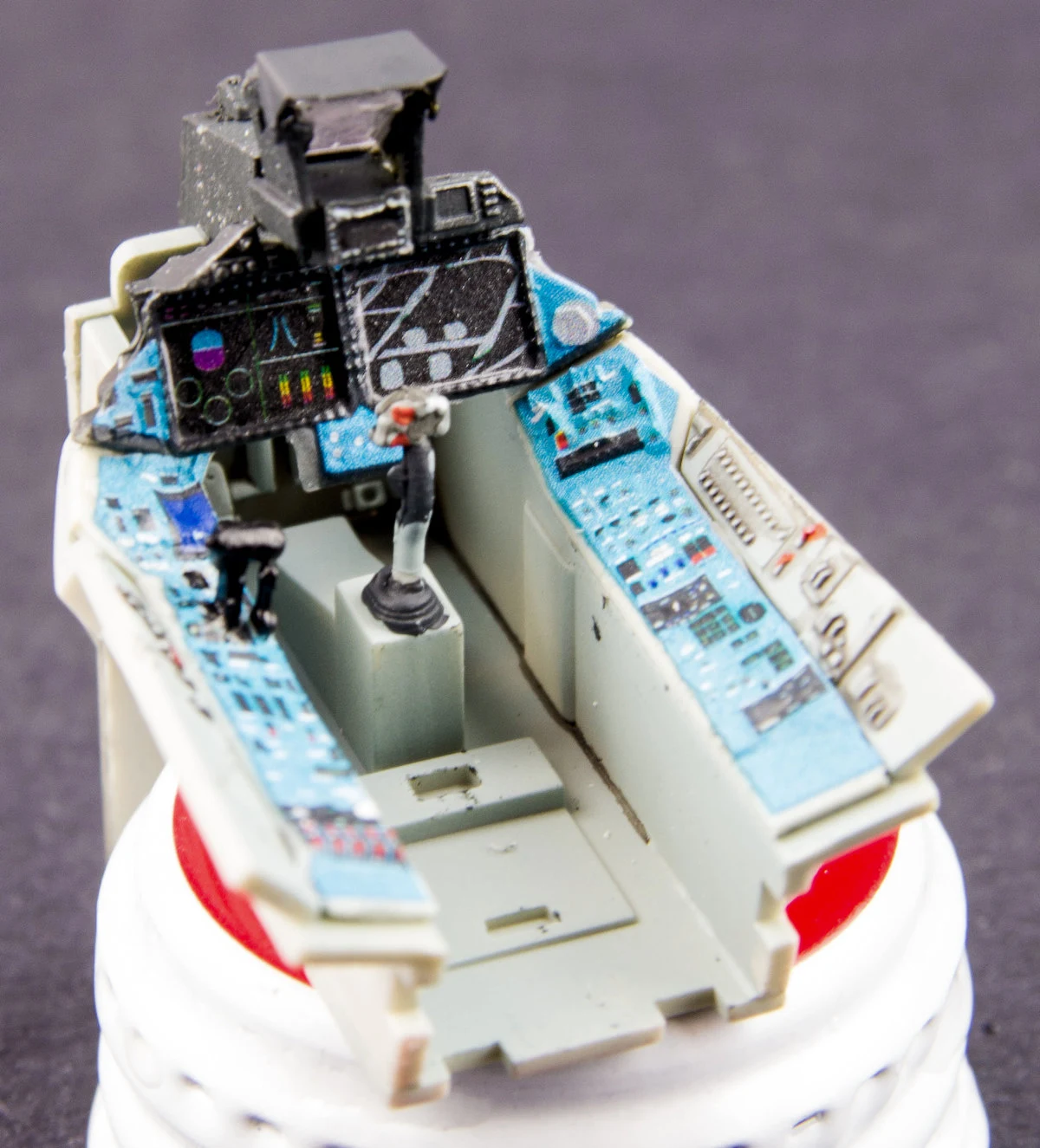

The cockpit tub assembles without a problem, although the parts suffer from some ejector towers and mould seams... I painted it using a mix of Tamiya light blue and light grey as I had no Air Superiority Blue

Being a review build I decided to use the kit decals, but regretted the decision.

The main panel decal shows powered up screens, with some dodgy graphics displayed on the right-hand screen, a modelling friend remarked it looks a bit like a crayon drawing! I think they would look better just painted gloss black. The side consoles out of the box have quite nice detail on them which the decals, apart from not matching, add nothing to. The colour also looks quite garish. My recommendation, don’t use them and just paint the panels, the moulded detail is fine.

The real thing in a mock-up in comparison

I found it took a little bit of brute force to push the HUD mount up through the cut out in the coaming. Perhaps don’t fit the frame, glass and PE sunshade until you have the tub in place. That way, it won’t get accidentally knocked off. I have seen photos of the HUD with and without the sunshade fitted so you could leave it off if you wanted to.

Before closing the fuselage, drill the holes as called out in Stage 2. Take your time joining the fuselage halves ensuring the mating surfaces for the wings are flush with no steps, otherwise you will be left with gaps when you attach the wings. Ask me how I know!!

Starting at the nose, I applied the glue from the inside and was rewarded with a nice join that will pass for a panel line when cleaned up

The rear of the fuselage is rebated to accept the base of the tail fins.

I left mine off to allow better access to painting the burnt metal areas at the tail. As you can see in the below photo the upper and lower fuselage halves have different profiles where the tail stinger joins.

Unfortunately what this means is that you cannot just simply mount the stinger on upside down so that the chaff dispensers are on the bottom as seen on all current jets.

There is a hole moulded into the lower fuselage which needs to be filled with a scrap bit of plastic rod as nothing locates into it. Also parts C91 and C92 should be E91 and E92.

Not bad though, we are12 steps in, and this is the first mistake I’ve found. A definite improvement on earlier kits from the same manufacturer.

Ensure parts C61 and 62 are glued in the correct way as otherwise, the intakes will not fit over them.

The intakes need a moulding seam removed from their outside lower edge before you fit them to the fuselage.

You should now have a more or less complete airframe ready for paint. It’s a decent size too

The next instalment will deal with the jet nozzles, landing gear and bringing the airframe subassemblies together.

Bruce Anders

Thank you to Kittyhawk Models for sending Bruce the kit to review and build