Brett Reynolds

is a very clean and thorough builder and has graced us here on TMN with many a

nice article and build – today he presents part I of II on the build of the

lovely kit of the Eduard F6F-5 Hellcat

in 48th scale. Today’s article concerns the build and

alterations he made to the kit whilst the second part will be the finishing and

painting of the Hellcat – Ok here we go…

Eduard Weekend Edition 1/48

Grumman F6F-5 Hellcat

Kit

No: 8434

Kit

type: Injection Moulded

Parts: 5x coloured

sprues, 1x clear parts sprue, 1x decal sheet

Build

Review by Brett Reynolds

Available

from Eduard Directly

at this link

Brett's build of the Eduard Weekend Edition 1/48 Grumman F6F-5 Hellcat - Pt II:Paint & finishBackground

The

Grumman F6F Hellcat was a carrier-based fighter aircraft conceived to replace

the earlier F4F Wildcat in United States Navy (USN) service. The Hellcat was an

erstwhile rival of the faster Vought F4U Corsair for use as a carrier based

fighter. However, the Corsair had significant issues with carrier landing that

the Hellcat did not, allowing the Hellcat to steal a march as the Navy's

dominant fighter in the second part of World War II, a position the Hellcat did

not relinquish (From Wikipedia).

The

Hellcat developed the reputation of a well-armed and rugged aircraft, which was

relatively easy to fly and maintain for carrier operations. In two years of combat, Hellcats shot down

5156 enemy aircraft in air-to-air combat, the most aerial victories ever scored

by on type of fighter. Only 270 F6Fs were lost in combat, resulting in a 19-to-1

kill ratio.

The

Kit

The

kit consists of the same plastic as the full ProfiPACK editions minus the

photo-etch, paint masks, resin wheels and multiple decal options. The plastic

is cleanly moulded with no imperfections or flashing, but I did notice a slight

misaligned in some of the parts such as the control surfaces and gun barrels.

The surface detail of the fuselage and wings is excellent with finely recessed panel lines and rivet detail. Surface texture of the plastic is smooth. Control surfaces are separate parts but are not positionable without modification. Options are provided for an opened or closed canopy utilising different parts.

The

instructions are printed as an A5 size B&W booklet - you can download them at this link.

The

Markings

As

with Weekend-Edition kits, only a single set markings is included. The markings

depict a F6F-5 in the standard USN overall Gloss Sea Blue finish, flown by Lt.

Leo Bob McCuddin of VF-20 off the USS Enterprise, October 1944. Lt. McCuddin

scored five victories over Japanese fighters in three combat engagements, all

in the space of six days. Although he flew “White 71” at least once in combat,

the six victory flags below its cockpit probably represent the aircraft’s

tally, rather than any single pilot (Source:

Osprey Aircraft of the Aces No.10).

The Build

As

with most aircraft kits, we start off with the cockpit. After a little clean

up, fit of the kit parts was straight forward, consisting of a cockpit floor,

rear wall, side consoles, seat and front instrument panel. Here the parts are dry-fitted with the

fuselage.

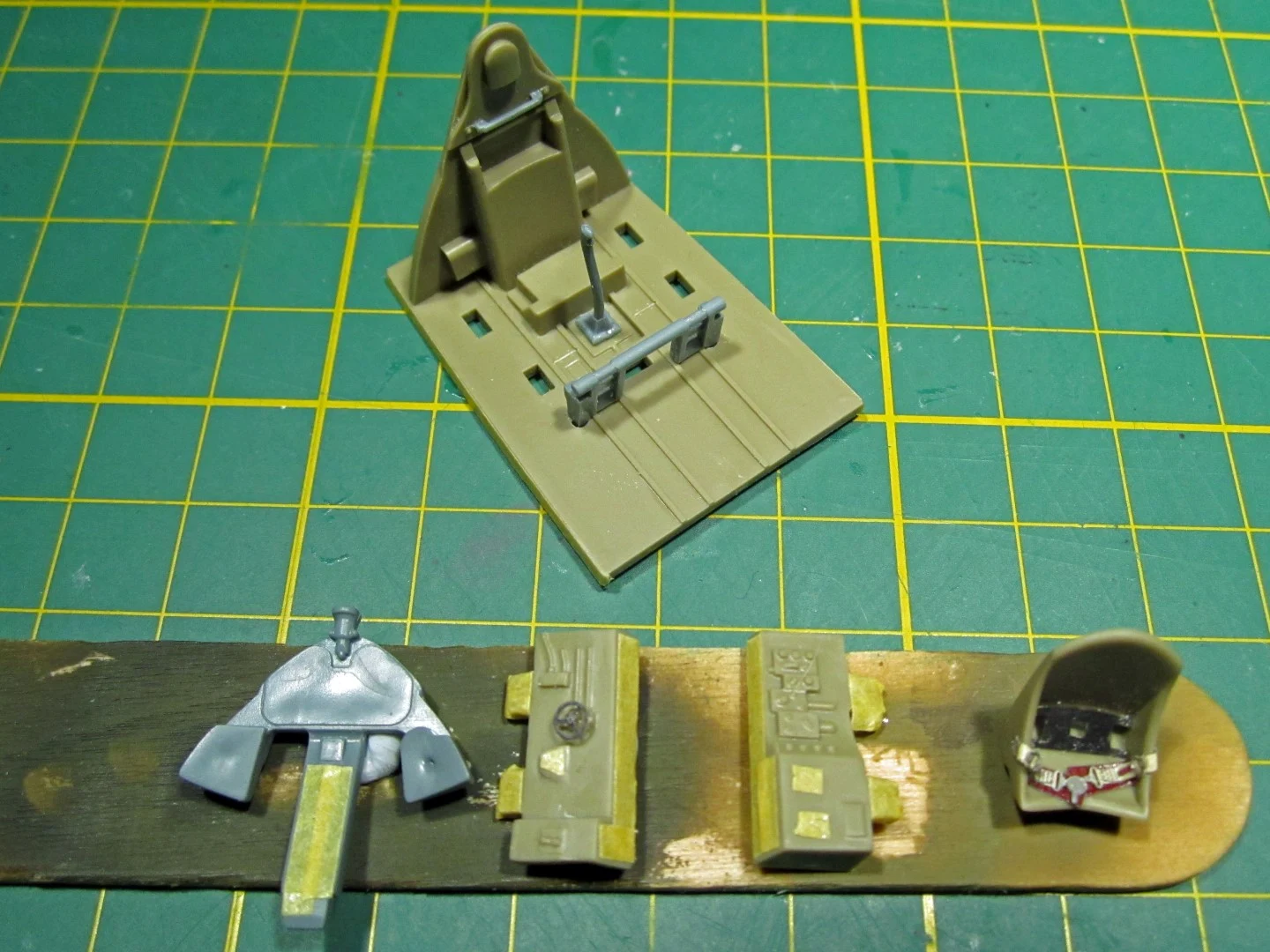

I decided to beef up the cockpit frame edge and instrument panel cowling with thin plastic strip for a more realistic look. Then dry-fitted with the cockpit parts to ensure there was no interference when the fuselage halves are assembled.At a minimum I would have added some seat belts to the kit seat but Eduard has released a Zoom photo-etch detail set (FE454) for this kit, which is virtually the same photo-etch from the ProfiPACK. For this build I decided to use a spare set from a F6F-5 ProfiPACK in my stash.

Since

I had already started gluing the kit cockpit before deciding to use the

photo-etch set, I had to pinch the cockpit parts from the other kit as well,

hence the change in colour of the plastic.

It

is necessary to remove certain raised details from the side consoles in

preparation for fitting the photo-etch parts.

The

kit provides a separate front instrument panel with no surface detail for use

with the photo-etch parts.

The

cockpit sub-assemblies were readied for painting. I placed masking tape over

the areas where photo-etch parts would later go. Never the best trying to glue

metal onto painted surfaces.

However

I did glue the lap belts in placed before painting. These were nicely

pre-painted, but I usually make a mess of gluing these after painting the seat,

so I decided to glue them into the position I wanted first and then repaint

them.

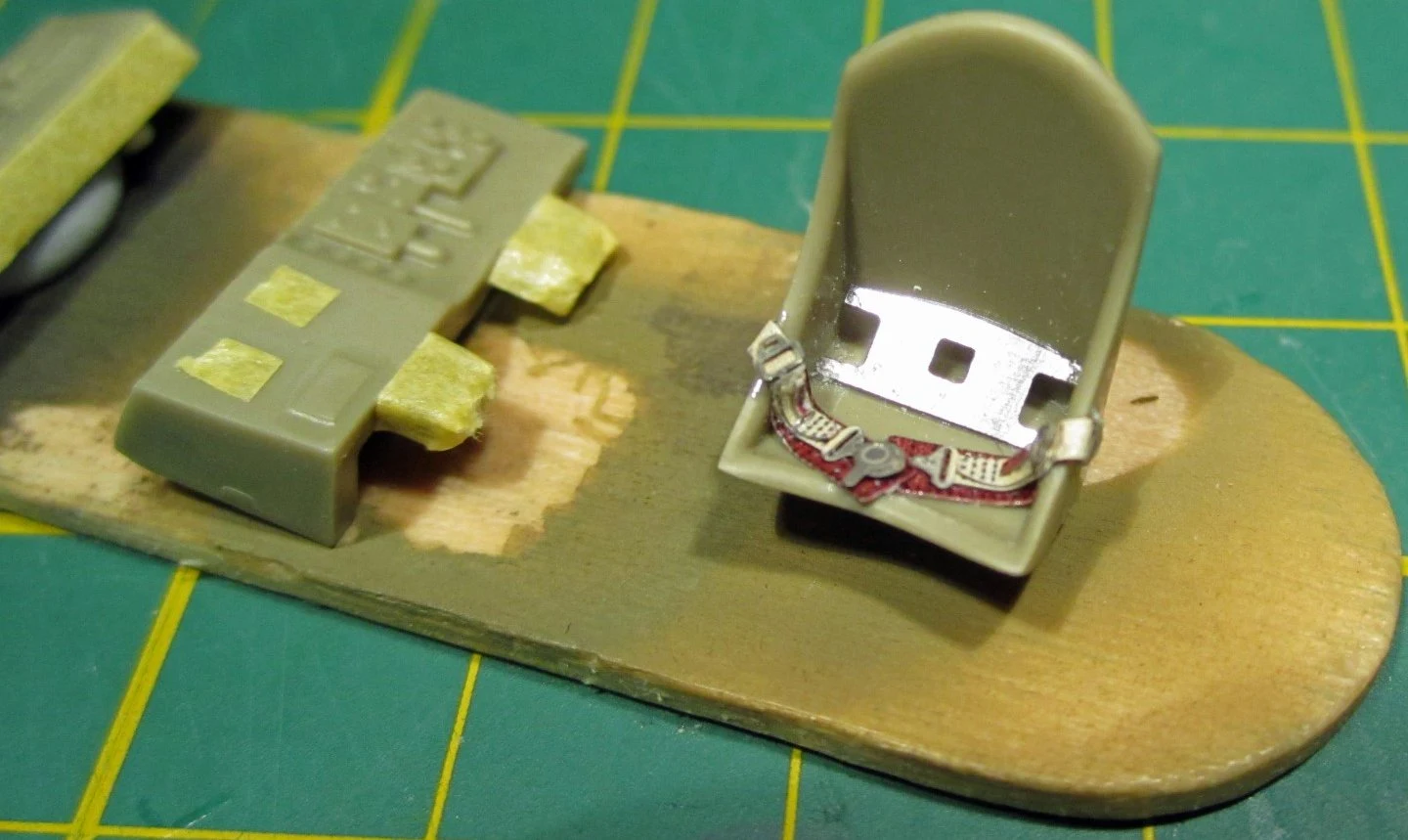

The

whole cockpit was painted in Model Master Interior Green FS34151 which was a

near perfect match to the Eduard pre-painted photo-etch. The pre-painted

photo-etch parts were attached with CA glue. Details were hand painted before

airbrushing a clear coat of Future. I

then proceeded with a light oil wash of burnt umber and a little dry-brushing

of Model Master Chrome Silver to highlight and represent worn paint coatings.

In hind-sight, I might have applied another coat or two of the oil wash to bring

out the detail a little more.

A

coat of Model Master Lacquer Flat Clear was airbrushed before final assembly of

the cockpit components. Note: a liquid latex masking agent was applied over the

instrument dials before the flat coat so they maintained a shiny glass look.

In-between

the painting of the cockpit, I started work on the sub-assemblies; cowling, stabilisers,

wings and engine.

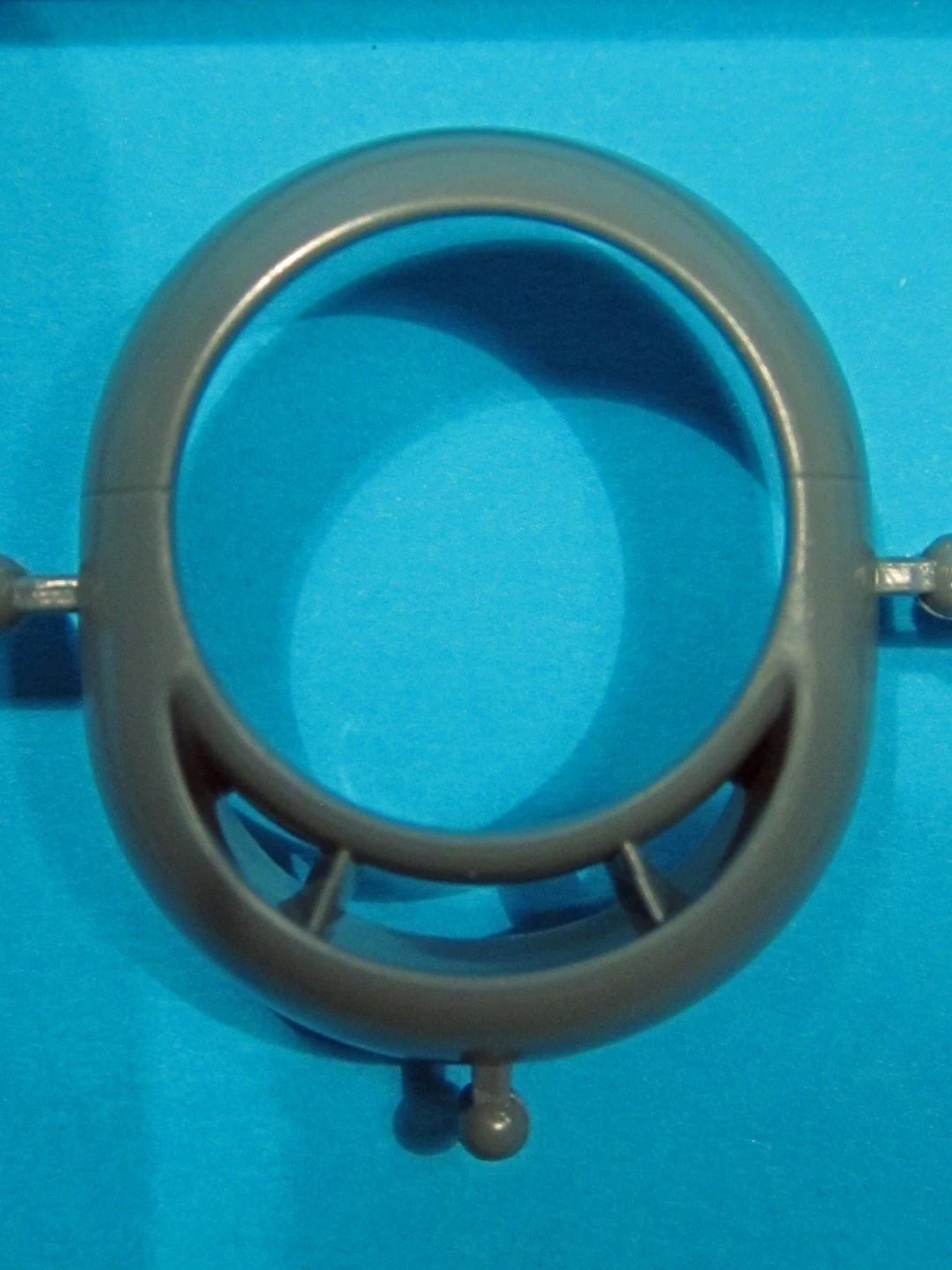

The

Hellcat has a distinctive front-end look with the lower chin intakes serving

the aircraft’s oil cooler, supercharger and intercooler. This shape has been

difficult to represent in injection moulding and resin replacements are

available, but I think Eduard has produced the best out-of-the-box attempt of

this part.

The cowling sides have ejection pin markings on the

internal surface which should be cleaned up.

Testing

fitting the cowling with the fuselage, I marked off the areas where the engine

exhausts poke through and where the cowling flaps are. I filed down the plastic

here to sharpen the trailing edge for a more realistic scale thickness.

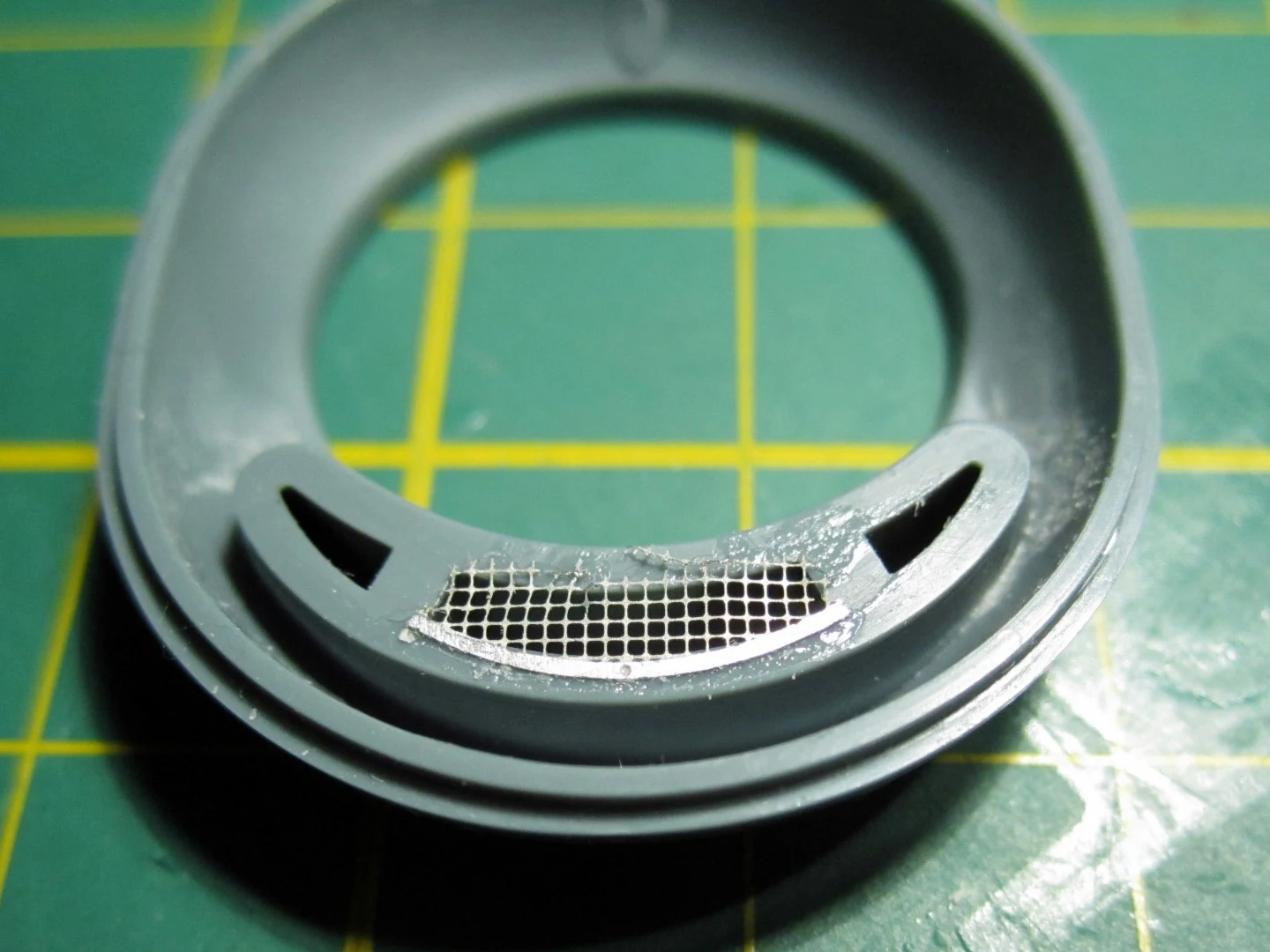

Some

fine mesh was added to the back of the supercharger intake.

The

cowling halves were glued to the front face one at a time. Note the correct

alignment of the horizontal panel line between the cowling front face and side

parts.

The

horizontal tail surfaces comprise of three parts; upper and lower stabiliser

halves, and the moving elevator surface. A large tab on the elevator slides

into a recess in the stabiliser which locks the elevator at the zero position. However, the elevators on parked Hellcats are

usually seen drooped so I decided to do some modification here.

A

special note; the stabiliser and wings have a stand-off peg at the inboard side

of the internal cavity which is there to hold the shape of the wing/stabiliser

to ensure a correct fit with the wing/stabiliser root in the fuselage halves.

So don’t go cutting this off.

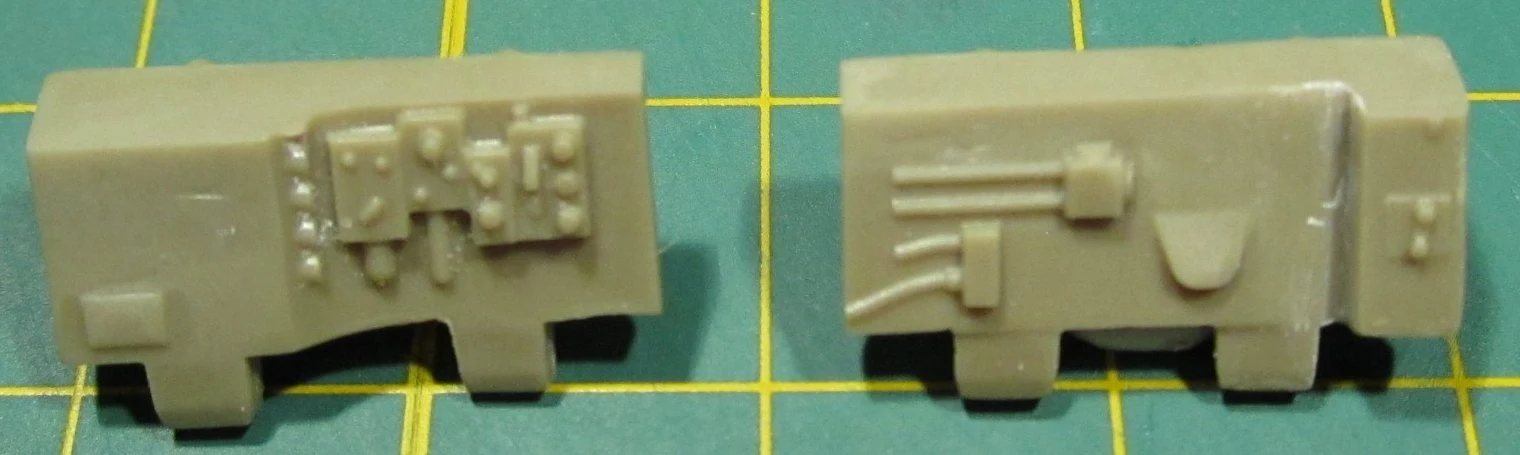

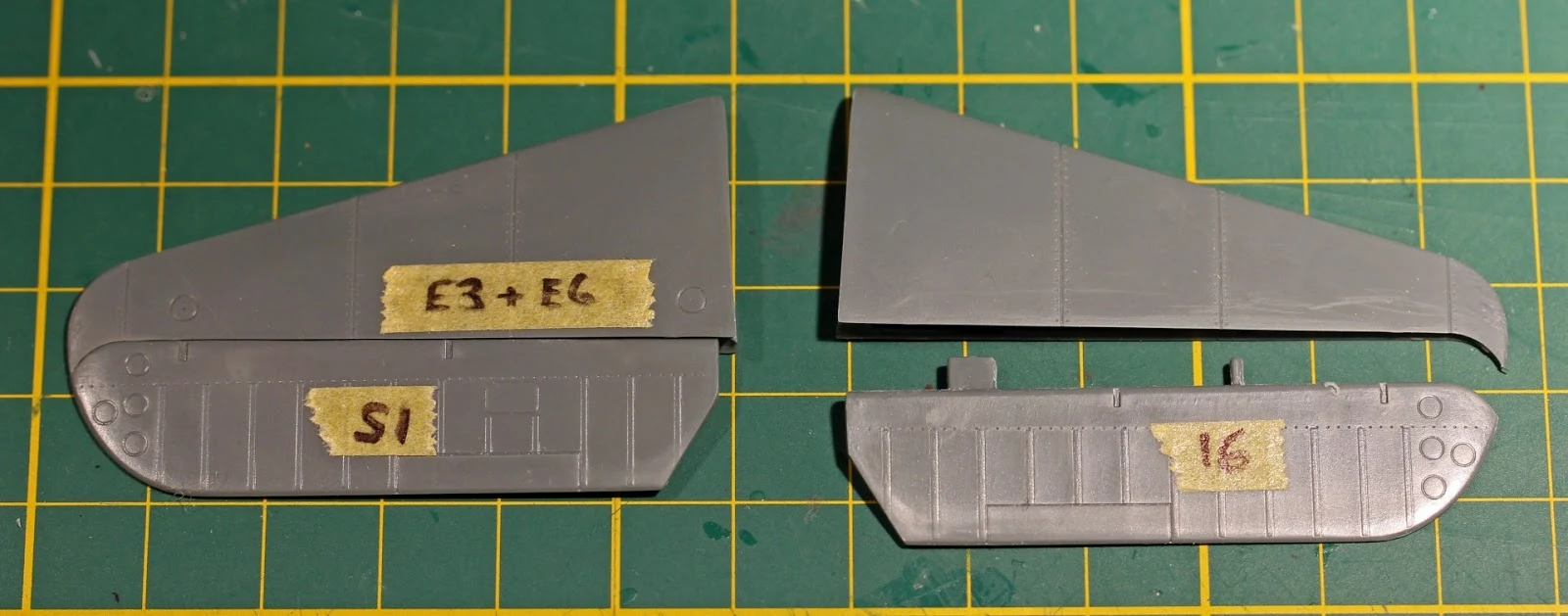

The

image below shows an unmodified elevator (top) and a modified elevator. The

recesses for the hinges have been cut out and the tab connections removed.

A

pair of hinges was made from plastic strip for each stabiliser. I could then

tape the elevator at the desired angle before gluing. I left this towards the

end to avoid accidental breakages.

Dry

fitting of the wings exposed a moulding alignment issue with the gun barrels.

Any attempt to clean these up would result in oval-shaped barrels, so I decided

I would replace them with brass tube at final assembly. The barrels were cut

off and recesses were drilled out of the block.

The

flaps were attached to the upper wing halve first then I added some tabs of

plastic strip on the trailing edge of the internal cavity of the top wing to

provide some extra support when assembling the wing halves. The wheel well and

gun barrel block were also attached at this time.

Like

the elevators, the wing ailerons have a tab which slots into their respectively

recesses. Like the gun barrels, the ailerons had an alignment issue and

required a bit of cleaning up and some plastic card to close up any gaps

between the wing and aileron.

The

wheel wells are nicely detailed out-of-the box and are finished off with a few

detail parts.

The

wingtip lights for the Hellcat are actually a coloured light with a large clear

cover. I drilled a small recess into the corner of the clear part and filled it

with the appropriate coloured paint.

The

light was super-glued into the wingtip and faired in. The clear part was then

sanded and polished to a smooth finish.

The

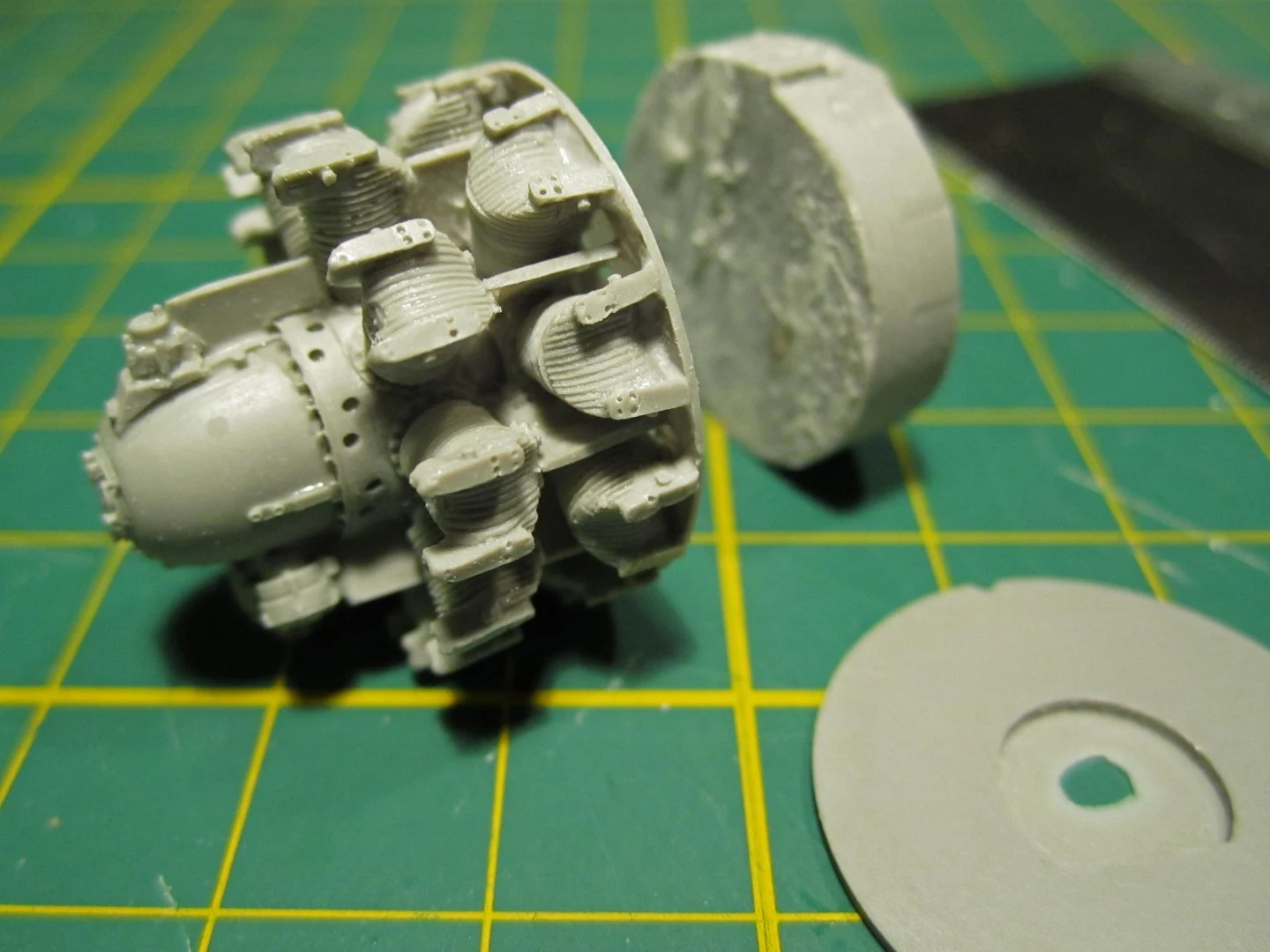

detail of the kit’s P&W R-2800 engine is reasonable and could be painted up

to look the part, but I decided to replace it with a resin engine from

Quickboost. The resin engine requires a bit of clean-up to remove the casting block

and the thin casting tabs behind each of the cylinder heads. It should be noted

this resin engine is not suitable if you want to do the full open engine display.

Eduard Brassin does a very nice R-2800 for this purpose. The Quickboost is

great for improving that front-end view.

To

fit the Quickboost engine, cut off the kit’s attachment point, leaving about

1mm.

Two

things missing from the Quickboost resin engine for the builder to add are the

push rods and the ignition wiring harness. The pushrods were made from brass

tube with the wiring harness from copper wire.

I’ve

read a few reviews and comments saying the chord of the three-blade Hamilton

Standard propeller being too large. I probably agree with that, but with some

sanding, the blades can be reshaped. Below is a pic of the kit part next to a

painted prop from a Tamiya 1/48 F4U-1D kit which is the same propeller.

To attach the propeller to the

resin engine, I drilled out the engine and inserted a length of 2mm diameter

aluminium tube. The propeller hub received a piece of styrene plastic tube,

drilled out to match the aluminium tube. You can also see in this image the

in-progress painting of the engine. The crankcase was painted in neutral grey;

the cylinder heads flat black and dry brushed with aluminium. The whole thing would

receive a oil wash mix of black and burnt umber.

The

tail wheel required a little clean up. The lightening holes were drilled deeper

for more realism. The tail wheel needs to be attached when joining the fuselage

halves together.

The

main landing gear and locking mechanism is acceptable but I removed the moulded

on wiring and replaced it with copper wire.

The

main wheels are provided as separate tyres and wheel hubs. Assembled, I found

the main wheels to look a little narrow at 4.3mm wide; this is more associated

with the prototype aircraft. I thought the tyres from the Tamiya 1/48 F4U-1D

kit were closer to the correct scale width at approximately 5mm. I added a

spacer to the gluing edge of the tyre. It’s important to remember to add a

spacer to the wheel rim as well to match the added width of the tyre.

There’s

no tread on the kit tyres, so sanding the widen tyre smooth is not a problem. There

are aftermarket options available if the builder wants a tyre with tread.

The

fuselage halves line up very well but the locator pins are very small and give

way easily. Take your time and you’ll have minimal clean up on the seam. Areas

that I found needed the most clean up were forward of the canopy and underside

around the oil cooling air intake. Don’t forget if you want to use the external

fuel tank to cut out the tab in the fuselage aft of the oil cooling air intake.

If

your dry fitting while assembling the wings and stabilisers was successful,

joining them to the fuselage should be easy. The kit is very well designed and

the fuselage wing/stab roots hold their corresponding parts at the correct

dihedral.

Any

small gaps in the wing root were filled with Milliput and smoothed out with

water before it cured.

The

kit external fuel tank, while appearing to be correct in size and shape, it is

missing the prominent centreline seam that runs round the tank. There is also a

version of this tank that has the seam running horizontally. Quickboost make

both these style of tank.

The

tank is secured on the real Hellcat with the help of two metal banding straps,

Quickboost provide these as photo-etch metal parts. Referring to my references

these straps go round the tank and go vertical until attaching to the aircraft.

I first glued the tank to the slot which was cut out of the bottom of the fuselage.

Gluing one end of the first strap in position I quickly learnt the photo-etch

metal straps were too long, nearly reaching the wing.

The

Quickboost instructions weren’t much help when trying to work out if I did

something wrong, so only solution I had was to cut the straps in half, then

trim the length of both so they meet up in the middle of the tank underside.

Another

small improvement was to replace the kit’s solid engine exhausts with 1.2mm

diameter brass hallow tube.

Almost

ready for painting; first was to mask and paint the canopy both sides with the

Interior Green colour used for the cockpit. The front canopy was then glued to

the fuselage.

OK that is it for the construction - on to the painting and finishing to show you just how good a result Brett got from this simple kit in Pt II tomorrow..

Brett Reynolds

Thanks to Eduard for sending us this

hellcat kit to build – you

can get it at this link from the Eduard Website

References

Aero

Detail 17 – Grumman F6F Hellcat (1996)

Dann,

Richard S. – Walk Around No.9 – F6F Hellcat (Squadron-Signal Publications

1996).

Kinzy,

Bert – F6F Hellcat in Detail & Scale (Squadron-Signal Publications 1996).

Tillman,

Barrett – Hellcat Aces of World War 2 (Osprey Publications 1996).