The late war wonder-aircraft that is the Dornier Do335 A-0 “Pfeil” has now been kitted for the second time in 32nd scale, this time in the Super Wing Series from Zoukei-Mura. We have been lucky enough to get one to examine the box contents and through a bit of researching and careful thought, we made a review of what’s in the box. Check it out in our detailed review…

In Boxed: Do 335 A-0 Pfeil

From Zoukei-Mura

Super Wing Series No.# 10

Super Wing Series No.# 10

1:32nd Scale

Total Parts: 353

Includes canopy masks, decals & clear parts.

Price: 16800 JPY/ USD$160 / GBP£101.

Price: 16800 JPY/ USD$160 / GBP£101.

Today we are looking at the new kit of Zoukei Mura's new 35th scale Dornier Do 335 A-O “Pfeil” or “Arrow” as it was called. The two-seater trainer version was also called Ameisenbär ("Anteater") because of its humped back fuselage. Before we get into the kit, we thought we might look at a few cool pictures of the aircraft and delve a little into the history of the type, and the actual particular aircraft this kit was measured against and modelled on.

A little history of the Dornier Do 335.

Claudius Dornier had patented the push-pull engine layout in 1937, which was innovative for the time as it offered the power of two engines with the benefit of less drag and greater manoeuvrability than other twin-engine configurations. The RLM (German Aviation Ministry) wanted to support the development of push-pull aircraft but initially only as seaplanes and bombers. By 1942, the Luftwaffe needed multi-role fighters and after submitting a proposal in January 1943 for a Schnellbomber (fast bomber), Dornier build a prototype Do 335 V-1 (‘V’ for Versuchs or experimental) and the aircraft fighter in September 1943. Following initial testing, the RLM ordered 14 prototypes, ten pre-production aircraft with the suffix designation A-0, eleven production A-1 single-seat aircraft, and 3 A-10 and A-12 two-seat trainers.

Dornier selected two Daimler-Benz DB-603 V-12 cylinder engines to propel the four different versions of the Do 335. Each engine displaced 44.5 liters (2,670 cu in) and weighed 910 kg (2,006 lb). Unlike conventional twin-engine aircraft with wing-mounted engines, the Do 335 would not yaw sharply to one side if one engine failed, and single-engine flying speed remained respectable at about 620 km/h (345 mph). Pilots reported exceptional flight performance in acceleration and turning radius, and docile handling with no dangerous spin characteristics. In an emergency, however, the pilot could detonate explosive bolts and jettison the pusher three-blade propeller and dorsal fin to increase the chances of successfully bailing out using the pneumatic ejection seat. When fired, the seat pushed the pilot away from the aircraft with a force of 20 Gs.

The aircraft had a unique design in that it had two engines but only a single fuselage. The two liquid-cooled inverted V-type 12 cylinder DB 603 engine made by Daimler-Benz was installed in the nose in front, while the other was placed in the tail in a "push-pull" layout. VDM propellers—one mounted in front and one at the back, sleek design and huge power gave the aircraft phenomenal performance. The Do 335's innovative design also featured an ejection seat and tricycle landing gear.

For a fighter aeroplane, the Do 335 was enormous: tall enough that a person of normal height could walk beneath it and very heavy at 9,600 kg (21,000 lb) loaded. Serious flaws also plagued the design. The rear engine often overheated and the landing gear was very weak for the weight of the aircraft and prone to failure in the case of a rough landing.

The Dornier Do 335 was one of the fastest piston-powered aircraft ever flown. Indeed, at a time that the official world speed record was 755 km/h (469 mph) the Germans claimed that a pilot flew a Do 335 at a speed of 846 km/h (474 mph) in level flight.

Do 335 specifications

Dornier Do 335 A-0 Pfeil (Arrow)

Manufacturer

Dornier Werke G.m.b.H.

Type: 12-cylinder liquid-cooled inverted V-type engine with supercharger

Bore x Stroke: 162mm×180mm

Displacement: 44.52L

Dimensions

Other: 197 x 545 1/4 x 519in. (500.4 x 1384.9 x 1318.2cm)

Overall: 16313 7/8lb. (7399.9kg)

Length: 2,610.5mm

Diameter: 830mm

Supercharger: centrifugal supercharger

Output capacity:

Take-off power: 1,287kw (1,750PS)

Cruising power: 1,111kw (1,510PS)

Compression ratio: 7.5: 1 left block, 7.3: 1 right block

Armament

1 × 30 mm (1.18 in) MK 103 cannon (as forward engine-mounted Motorkanone)

2 × 20 mm MG 151/20 cowl-mount, synchronized autocannons

Dornier finished building as many as forty-eight Do 335 aeroplanes and another nine or so were under construction when the war ended. One of many plans issued by the RLM called for Dornier to build 310 Do 335s by late 1945. Although several pre-production aircraft were issued to combat conversion units about 10 months before the war ended, no pilots flew Do 335s in combat, although there was an account of the type confronting a French pilot in a typhoon in 1945.

Only one example of the first production version Do 335A-1 left the Dornier line at Friedrichshafen just before the war ended. It was armed with one 30 mm MK-103 cannon (70 rounds were carried) firing through the propeller hub and two 15 mm MG-151/15 cannon (200 rounds per gun) firing from the top cowling of the forward engine. The aircraft was also equipped to carry an internal bomb load of 500 kg (1,100 lb).

The second Do 335 A-0 built is displayed at the NASM's Steven F. Udvar-Hazy Center. Dornier designated this airframe construction number 240102 and gave it the aircraft identification code VG + PH and A-02. Craftspersons completed the aircraft at Dornier's plant at Mengen, Germany, on 30 September 1944, and then test-flew the aeroplane during the winter of 1944-45. From 20-23 April 1945, German test pilot Hans Werner Lerche flew the Do 335 from Rechlin back to Oberpfaffenhofen near Münich, via Prague, Czechoslovakia, and Lechfeld, Germany. Allied forces found the Do 335 at Oberpfaffenhofen on April 29.

In mid-June, pilots ferried two Do 335s, including the NASM aircraft piloted by German test pilot, Hans Padell, from Oberpfaffenhofen to Cherbourg, France, for shipment to the USA aboard the British aircraft carrier HMS Reaper, along with other captured German aircraft and equipment for technology evaluation.

Following U. S. Navy testing from 1945-48, the Navy transferred the Do 335 to the Smithsonian's National Air Museum in 1961. The Do 335 remained stored at Naval Air Station Norfolk until 1974 when the Smithsonian returned it to Oberpfaffenhofen, Germany, where the Dornier company preserved and restored the aeroplane in 1975.

Dornier craftsmen, many of them factory employees since World War II, were surprised to find still attached to the aircraft the explosive bolts designed to blow off the tail fin and rear propeller. Dornier displayed the preserved aeroplane at the May 1976 Hannover Airshow, and then moved the artefact to the Deutsches Museum in Munich until the aircraft was returned to the Paul E. Garber Facility for storage in 1986.

This Do 335 A-O is now on display in the Boeing Aviation Hangar at the Steven F. Udvar-Hazy Center in Chantilly, VA.

It was this sole remaining aircraft Dornier Do 335, WNr. 240 102, that the team at Zoukei Mura measured and researched in in the Udvar-Hazy Center of NASM. The aircraft belongs to the zero series A-0 and that is the exact scale model we are looking at in this boxing. The link is here of their visit on the “Old Man Blog” from the president of Zoukei Mura.

Zoukei Mura has been operating it's “Super Wing” aircraft series for a few years now, and after bursting onto the scene with “Tamiya-like” comparisons of their kits initially, the phrase “ZM-Like” is not a thing. It stands for attention to detail and accuracy, with period like authenticity added to the mix – ohhh and a dash of a lot of heart. This is the feeling I got when I made their 32nd scale Ho-229 for a review build a year ago. It struck me that the effort that went into the kit was far more than any I had seen before with the instructions and the way if that is a thing – the way of making the model. Everything flowed from sprue to sprue. The closeness of the parts that always just seemed at hand close to where you cut the last one from the sprue. I cannot speak highly enough of the building experience. That kit had a heart.

So it was after this kit I went about investigating ZM's next release – the just as ambitious Do 335 in the same large 32nd scale, and BIG it surely is! The box comes in at 53cm long X 30 cm and about 10 cm deep. There is another, hardened cardboard box inside to make sure that all of the parts arrived safely. Nothing was broken inside when we opened it up.

Inside the box you will find several elements of the kit, each securely wrapped up in its individual plastic, included here are:

Contents:

A total count of 353 total parts

Seven sprues in light grey plastic

Four sprues in clear plastic.

one canopy mask

One decal sheet

A large, full-colour instruction and painting booklet.

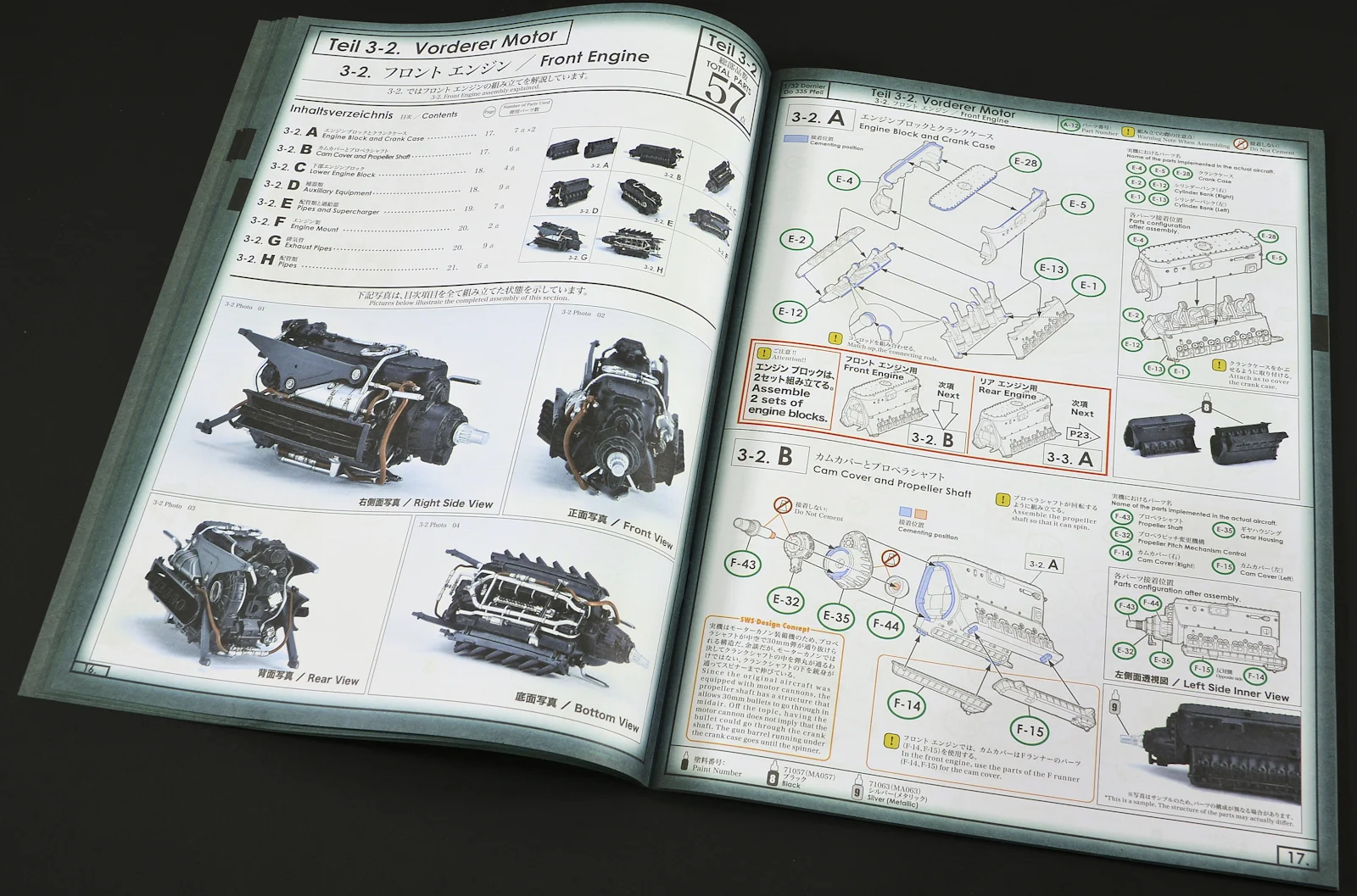

The instruction booklet in this kit is firstly very much like something you see in period user manuals. All of its fifty-four pages are printed in colour, and all have the look and feel of something is written way back in the past. The colours, fonts and drawings inside are very immersing and put you right into the mood of making a replica reminiscent of the scene set by the Instruction booklet.

A short introduction and overview of the aircraft in real life and some of its features are great fodder for an enthusiastic modeller wanting to immerse him/herself into the task at hand.

We start the construction in the cockpit as one might expect. There is nine-page of detailed instructions here, and as you might see right throughout this booklet, the basic instructions are packed with that extra information about the parts of the instruction in English are added at important points. These extras make the instructions dense, but if followed pretty fool-proof for just about any modeller's talents.

The alternates of the instrument panel are included at this juncture in the instructions. There are five different ways you can put together this particular, but very important part of the cockpit using the clear and the grey plastic instrument panels we will look at later on in the review.

The first of the two DB 603a engines is next, in the six pages of the construction process. The engines require nothing much more than what is included here in plastic to make them look very realistic.

The second engine is at the rear, and it is almost a replica in the construction of the front engine (as one might expect) but the instructions do not skimp on detail. As with all of these sections, the kit in the instruction being worked on is shown in colour pictures, painted up in detail so one can copy (the best form of flattery) as much as possible the high standard of the model to emulate with their own kit.

Next, we see the Fuselage (Rumpf) put together in six pages of instructions. being that the engines are mounted in the fuselage you also see these parts of the kit going together - with the engine display stands of which we will be talking about later.

The Main wings are next. there are four pages of how they go together, with the fit of them very important to the end product. The lugs they use to fit together and all of the other gear inside these exposed wings is walked through, with the landing gear bays and large wing fuel tanks a highlight here of the finished construction.

Next, we look joining the fuselage and the wings together. The posing of the flying surfaces and other details.

We then switch to the landing gear, how it fits, tips about the order of construction and finer points are again explained in the English text.

"Final outfitting" is last of all, do you notice that up in the right corner there is a number of parts needed for each of the parts of the construction? All of the final parts are covered until the aircraft is ready for its external paint.

There is only one version of the aircraft in the painting guide. However the fact that this one aircraft is featured so heavily in the making of this kit by the manufacturer, and the authenticity of the colours being beyond question, it kind of makes sense. Colours are pointed out in the Vallejo made colour sets that ZM sell, however not many modellers will use.

Oddly, we have the sprue map at the end of the instruction booklet - this will help us talk about the sprues as we go through them next.

The decals are printed on one sheet of eighteen centimetres by seventeen centimetres, there is only the option for one aircraft, and although the decals are of excellent quality, register and colours, however, I would have liked to have seen these in more variations, maybe experimental choices.

The vinyl mask to fit the canopy is included. Maybe Kabuki tape would be a slightly better choice as Vinyl does indeed shrink over time, and shelf queens who keep this model for years before they make it might need to improvise. If you are making it within a few years you should be ok though.

The Plastic

A note before we start to look at the sprues. The 353 total parts come from the combination of seven sprues in light grey plastic and four sprues in clear plastic. the light grey plastic is of a pretty normal feel and quality. The clear sprues are of a different make up altogether. The plastic of these parts is of a stiffer and harder plastic, more prone to shattering than bending, this is not a big deal, but something of note when handling these sprues.

The sprues feature very little excess material and flash, seam lines are kept to a minimum but they are still present at times. The use of slide moulds helps create great details like hollowed out gun barrels and exhausts. Great stuff in the moulding department from the manufacturer, a real modeller's eye is present in the results of this kit. Compromises are made, but only when completely necessary to save on outside surface detail.

The clear plastic is also frosted, so those wanting to display the extensive internals and all of the hard work involved and able to be shown off in construction will not be really visible unless you polish the plastic on the insides. The great work on eliminating the ejector pin marks then shows up on the inside. This can not be avoided, but it should be said about this plastic type in any review.

The Sprues

Sprue A: There are two fuselages halves that dominate Sprue A. This and the larger engine covers and ports are all here. Like all of the sprues in clear, be careful when removing parts and sand them to the cutting point rather than risk it (for a biscuit).

The large vertical tails are of a smooth, flush-riveted skin surface with all of the inspection ports. there are fine rivet sports along the seams of the joints which is realistic. Connection points are in sensible places where they can be - note that the inside of the tail is where the runners meet the model.

The shot below is of the inside of the fuselage. The control wires and lines are moulded into the clear plastic here, but you would want to add a few more of your own for more of a 3D effect.

The shot below is of the inside of the fuselage. The control wires and lines are moulded into the clear plastic here, but you would want to add a few more of your own for more of a 3D effect.

The riveted insides of the main gear covers are finely executed and a wash over the paint will further enhance that.

The large vertical tails are of a smooth, flush-riveted skin surface with all of the inspection ports. there are fine rivet sports along the seams of the joints which is realistic. Connection points are in sensible places where they can be - note that the inside of the tail is where the runners meet the model.

The riveted insides of the main gear covers are finely executed and a wash over the paint will further enhance that.

The cover of the rear fuel tank is again nicely detailed in the spine, and the fact that these plastic joints run ALONG panel lines instead of just down the seam makes construction a whole lot easier. The internal brackets are also here for anyone who wants to display the fuel tank opened up to the elements and cover exposed to see the innards.

Below the fuel cover in this picture (above) is the nose twin MG cover with opened up barrel holes.The raised "flutes" on the front of the nose are replicated here also.

The exhaust shroud cover is again riveted at the right points, however, if you want to show the insides of the overexposed you will have some (admittedly thin) ejection points to sand down.

Sprue B

Sprue B

This large frosted clear sprue houses the massive wings of the Pfeil. The flaps and wing control surfaces are here. You will need of course the grey plastic framework of these wings to sit them around. Ribbing is included on the inside of the wings as well as the interior of the landing gear bay.

The surface detail of the wings is important with models, and this kit's wings have the puttied over or flush riveted smooth finish that helped give the Dornier it's extreme speed you can see here on the top half of the wing the internal ribbing and rivets that will again, come out very nicely under a grimy wash.

The surface detail of the wings is important with models, and this kit's wings have the puttied over or flush riveted smooth finish that helped give the Dornier it's extreme speed you can see here on the top half of the wing the internal ribbing and rivets that will again, come out very nicely under a grimy wash.

The undersides of the wings have more ribbing and location tabs to seed the wing fuel tanks inside.

Some (grainy) pictures below the wing showing a similar flush surface detail over most of the wing.

That wheel well detail closer in (from above though you can still see it through frosted plastic)...

Sprue C

This sprue is again moulded in that frosted clear styrene, and it features the wing root covers, the front engine cowling covers and those large wheel well covers.

These wing root spas are pretty thin, they are moulded almost all in one piece also, so there is no front and rear seam to look after when this goes into place. Great for modellers as we all need the time to do other things than pestering over wing root seams.

These wing root spas are pretty thin, they are moulded almost all in one piece also, so there is no front and rear seam to look after when this goes into place. Great for modellers as we all need the time to do other things than pestering over wing root seams.

The front cowling halves are here replicated in that frosted plastic. The internal structure is there so all you need to do if you want to show them off is eliminate those thin ejector pin marks.

The covers for the wheel wells are here on the clear sprue also - the attachment points to secure the covers over the landing gear are here in small indentations. Structures of the internals are again faithfully replicated.

The air intakes are cast in thin, rounded off plastic parts, the large pointed oval shape of the rear engine air intake is very impressive in shape.

Sprue D

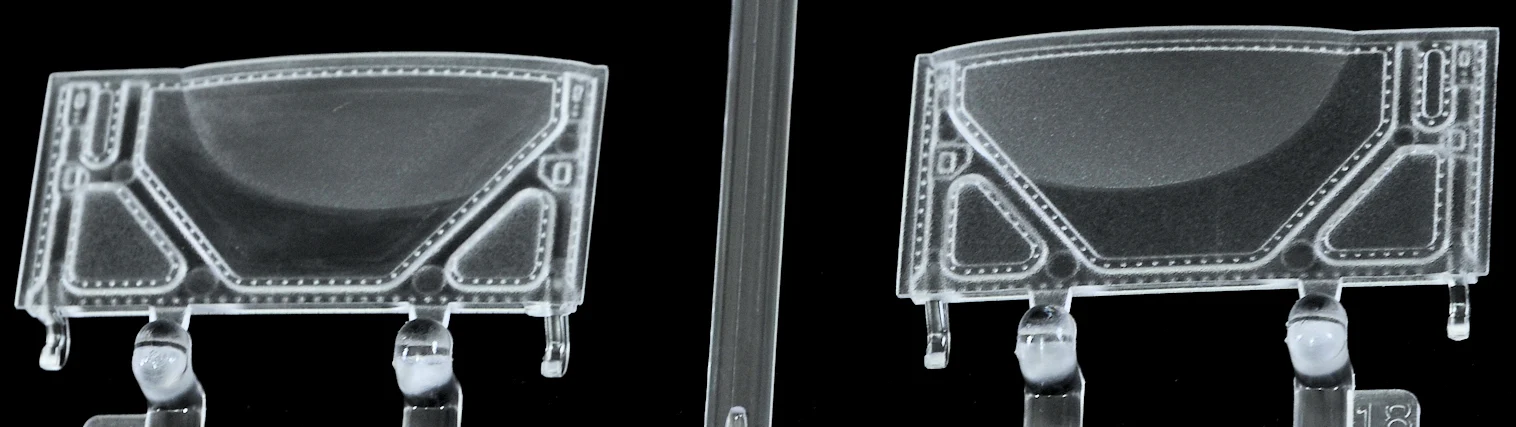

This sprue is another, this time clear plastic sprue that contains a lot of the smaller aspects of the control surfaces and nose cone, the front windscreen as well as the clear version of the instrument panel.

The cone of the nose is taken up with three circular parts, so no nasty seams around the nose to take care of, like a lot of other parts here in this kit the join is at a natural juncture.

The instrument panel, clear wing contoured covers of the landing lights, and wingtip navigation lights are here on this sprue, along with some frosted parts, it's funny that the whole thing just wasn't moulded in a completely clear, but I have heard that the frosted texture makes the plastic less susceptible to cracks.

A close up of the instrument panel, and that of a restored version of this aircraft below. The dials are all in the right place, and this clear panel is one of the two ways of creating your own replica. This one will have to be painted by the modeller, with the clear dials masked off. The decals sit behind the painted face and bezels, giving real depth to the instrument panel, but it sure takes time and a skilled hand - we will leave it up to you...

The front windscreen of the A-O model was an unarmoured plexiglass screen. Later models had the armoured glass but this aircraft did not. The clear plastic on this sprue is without distortion so you can see all of the no doubt good work you have done on the interior. The shape looks great to me as well. Of course, this is the first part of the glazed canopy to use if you want to pose it open.

A very clear and thin transparency sprue is next. The highly arched canopy on the Do 335 is well represented here with the rear half of an open version (the front we just saw) and the whole front and rear of the canopy sealed together to show the aircraft buttoned up.

There is no seam on the high arch (phew) which is great because I hate willfully damaging the canopy of an expensive model in this scale.

A side-on profile of the perspex canopy. You know I cannot find a picture of the A-O that has the small flap in the port side or starboard side window...

Ahh, grey plastic - remember that? time to look at the skeleton of this bird on Sprue I. This sprue features the wing frames that secure to the fuselage with interlocking "L" shape boxes, wing fuel tanks and the shock absorbers and insides of the wheel wells.

The insides of the structures are delicate, and they house these internal wing tanks

A line drawing of these tanks in their position inside the front leading edge of the wings.

Closest to us in the view below is the internal "L" shaped bracket that fits into the other side opposite wing into a box-like shape that sits tightly and strongly in the fuselage.

A bottom looking up view of the underside of the wing. The stringers on the leading edge join up the long front edge and everything inside the wing fits in these two halves. They are too thick by far to be scale accurate, but they do give those who want to show the wings clear and open a little of what the structures look like. It is not really for rivet counters, but I think those interested in the aircraft and the internals of machines will like this.

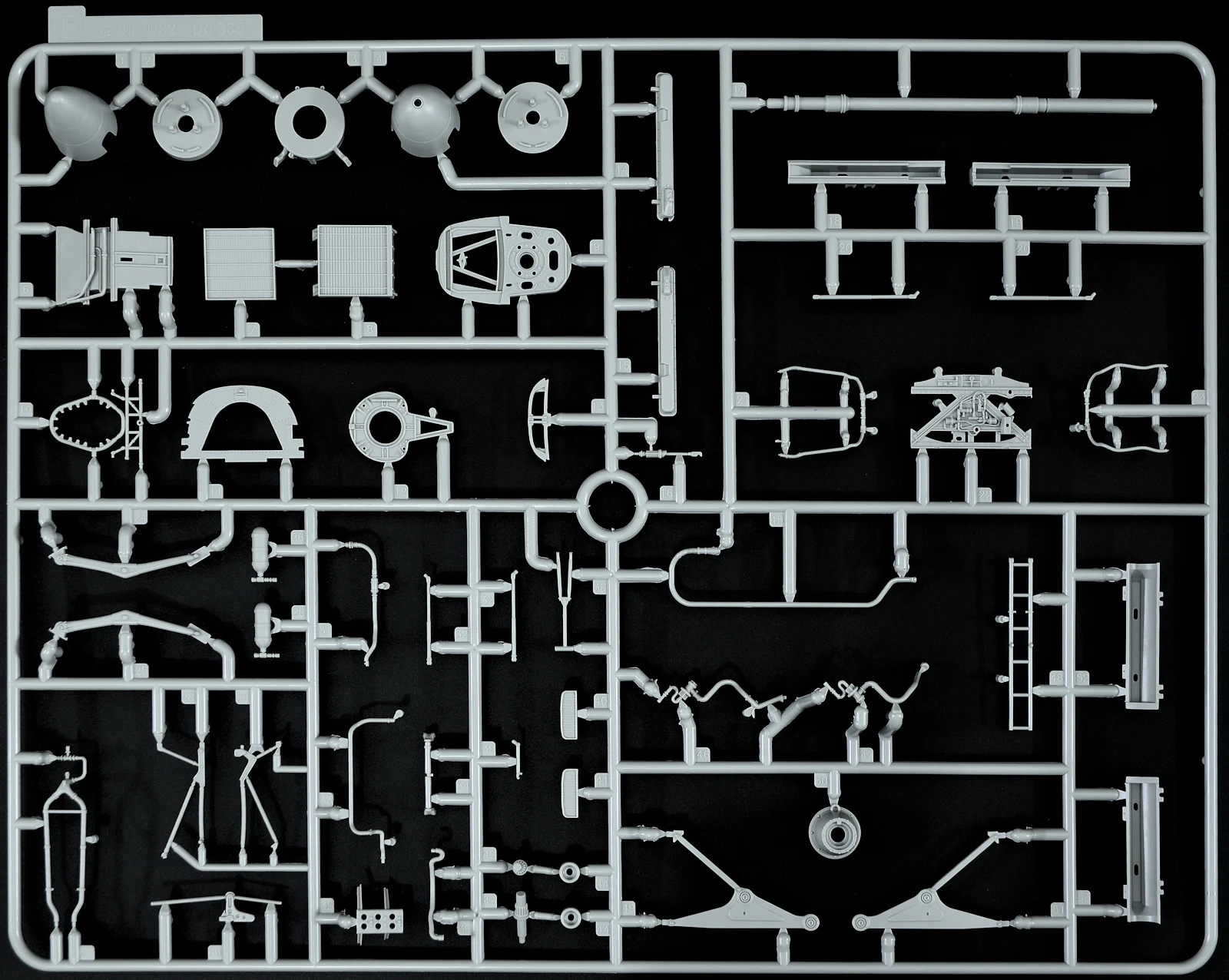

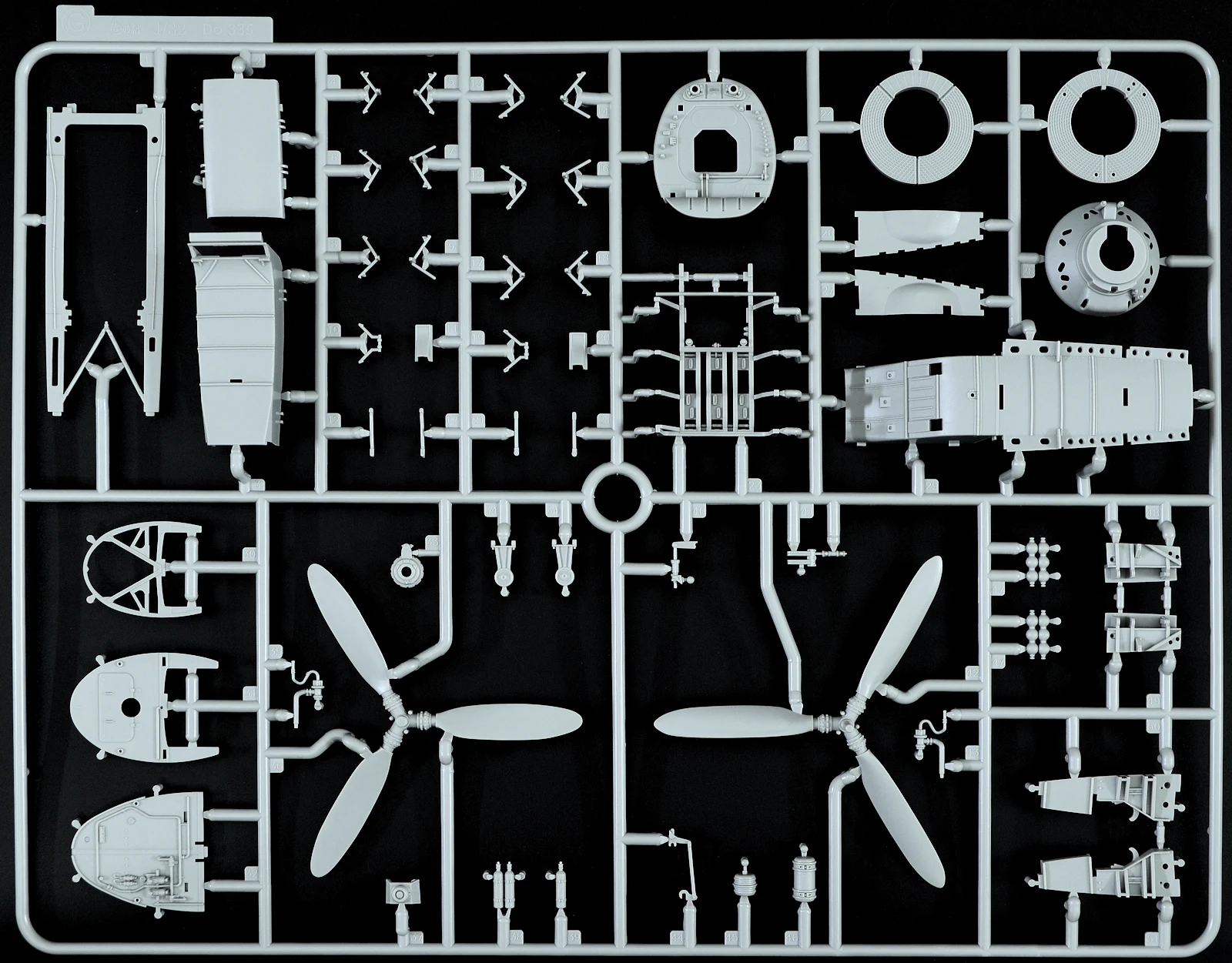

Sprue E (X2) is next.

These sprues, with a few other bits from Sprue F contains both the front and rear Db 603 engines. The sprue - if you are sharp eyed - you may see some square parts on the runner, these are from the engine stands that can be used to display either engine outside the aircraft on this little jig. Wonderful work from a thinking mind of whoever envisaged it.

Harnesses replicating wire and pipes are included. The plastic on such parts can often be a flash magnet, but there really is not very much extra material if all to be removed here, so that is some nice moulding work.

The engine block features something I looked for right away and I am glad it is here. The pistons and the rods are indeed again moulded in the engine. Once it is together - no one will see them - but YOU will know they are there - and that shared experience, the exposing of the insides of the aircraft to the modeller, this is part of the heart with which I talked about earlier - the passion of which it is obvious that the model maker exhibits all over this complete package.

The moulds are working overtime by the time we get to the exhausts of the Db 603's. These have the trademarked welded seams along them and the hollow ends that we as modellers sometimes go to exorbitant methods to replace. Moskit, whoever, I don't want to spend a fortune getting a pair of hollowed out, scale thickness exhausts when a kit maker can, with some effort, make something as nice as this on their kit.

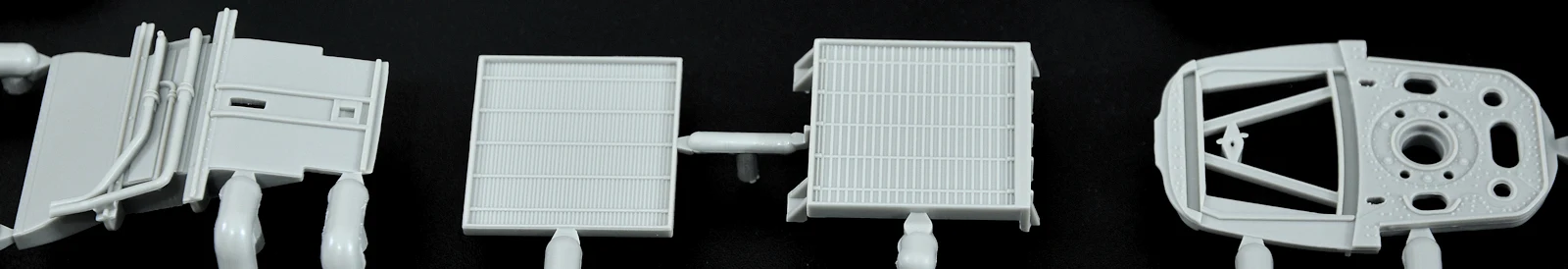

Sprue F is next, with the two propeller hubs (different sizes of course) some of the engine harnesses and the radiators, firewalls and engine brackets for the front engine.

The two VDM propeller hubs are here - the rear on the right is far more pointed while the front prop has the cannon shooting through the hub.

The very familiar engine brackets for the front Mercedes Benz engines are here in some nice detail that match the original.

More piping and plumbing of these engines is included in this sprue. The radiators and firewalls are also here, some of the firewalls may need some lead wire to be added to them for completists, while some might leave them as they are. They are already very full of detail. A kit like this screams for extra plumbing where appropriate I think, and if it cannot be moulded the modeller's dance card gets all that busier.

More piping and plumbing of these engines is included in this sprue. The radiators and firewalls are also here, some of the firewalls may need some lead wire to be added to them for completists, while some might leave them as they are. They are already very full of detail. A kit like this screams for extra plumbing where appropriate I think, and if it cannot be moulded the modeller's dance card gets all that busier.

Sprue G

Next, we see the smaller structural internal bulkheads of the aircraft, along with the two VDM propellers and some smaller cylinders and other more obscure, though detailed parts of the inside of the fuselage.

The shapes and diameters of these two propellers are different, so the designers made what I hear is a lot more measuring than would go into some of the other, simpler parts of the airframe to quantify. The front propeller (Part G36) is the wider bladed prop, a tractor propeller with a diameter of 3.5m. The trailing edge has a flat, almost trimmed surface.This is only able to be fitted onto the front prop shaft which is insurance against us that do not like to read instructions so much. Here it is in comparison to the real thing.

The rear propeller (Part G13) is slightly thinner than the front prop. The rear propeller is a pusher propeller with a diameter of 3.3m, and it is directly connected to the engines with an extending shaft. Thinner than the front tractor unit, it is slightly more pointed at the tip. Here it is in comparison to the real thing.

More of the detailed internal firewall, bulkheads, radiators, and framing of the internal fuselage is next. As you can see the connectors are sometimes there where the modeller is not given a plastic part to attach it to (more wires to be added) and the honeycombed radiator parts that will look so good when painted skilfully.

The second last sprue in the box is Sprue H.

This sprue is very busy, but really important to the modeller as it houses a lot of the interior of the fuselage including the cockpit floor, the large internal fuel tank, the main armament, version two of the instrument panel, the ejector seat and rear cockpit wall.

This instrument panel is the alternate choice for the modeller for this kit, it may be your first choice to paint and weather your own instrument panel with all of the dials and knobs, but it's good that the option is given here, and you can have the choice to make it up how you like. Again the panel looks uncannily like the restored version we have a picture of below

The cockpit floor is full of wiring detail that you probably would not need to add anymore too. The lugs for the parts help secure it all in, and the detail of the seats and equipment build on this very ood base of the cockpit.

The ejection seat is in nearly twenty parts when completely made up and in place. The moulded on straps are really a very good alternative to the aftermarket types, having made one or two aftermarket seatbelts before these are like an apparition from heaven. So easy and 3D enough to add some great depth to an area of great interest to any observers.

Either side of the pilot's cockpit wall is moulded on the two parts below, of course, added to with extras, but this is the sides of the "tub". The piping is there along with the radio on the right-hand side, it is all again, a good building base for the rest of the cockpit's parts and whatever you woud like to add yourself.

The side console panels are here in raised detail again. Thes will be easy to pick out in your model, and the rear bulkhead #5 on the right of this picture is the one between the cockpit and the feul tank. This bulkhead has the ejector seat rail on it.

The main weapons of the aircraft are the twin Mauser MG 151/20mm machine guns installed in the upper nose, the slide moulds Zoukei-Mura have used allow these long barrels that are very visible once the kit is finished with an open-ended tube at the end. You could drill these out further, but I am happy with these as is.

The Rheinmetall's MK ("MK" - Maschinenkanone) 103/30mm cannon that is located in the central section of the engine mount. The only known usage of the MK 103 in a Motorkanone installation was in the Do 335. This gun fires right out of the propeller hub like the earlier Bf-109's did. This heavy cannon is represented pretty well here, although once twisted and fit snugly inside the engine you will not really see it.

The kit has no bomb, though it has a very detailed bomb bay included that can be left open so you can see the details inside. The bomb was omitted in the spirit of keeping it close to the experimental A-O version of the boxing, however, if you are going to make a kit like this, unless you want to make another boxing (or two) then it would be good to include as much as you can to make the model attractive to all modellers, not just someone who likes the prototype.

Sprue J

Last but not least we have the sprue which houses the wheels and tyres, the landing gear, and two of the insides of the gear wall.

The main and nose wheels and tyres are separate on this kit, which make them convenient to paint and weather. As you can see from below, the plastic pretty closely follows the real thing. However, notice that the tyres on the Smithsonian D0 335 have "Dunlop" US made types without the ribbing of the German tyres of WWII like this kit provides. You will simply have to sand them on the centreline to provide some scale realness in this effect.

The rear landing gear is chunky just like the real thing, it has positive sockets that it fits neatly into on the kit, and it has brake lines moulded in plastic to attach to it. I think these will be strong enough for the kit to sit comfortably

The nose gear is just a little more delicate than the rear gear legs, however, I do think again it's sufficient. YOu will need to add 50 grams of weight to the front fuselage, but this is not a big deal with these gears holding it up. The nose gear is a pretty nicely replicated part when you compare it with the gear and oleos of the real thing below.

Phew - so that is everything in the box, so - what do we think?There is not another 32nd kit of this type in similar detail of the Do 335. Most people will love this. There are some that will like a more simplified version without all of the interior ribbings and structure. Take it from me, if you build one of these kits and want to show off the interior you will spend just as much time on sanding clear the frosted sprues and printing and glueing the insides to fit. Those who like the simpler approach might like to try the HK Models Do-335 or simply just build this kit and close it all up without painting the insides - easy!

However, if you are of the other inclination, the type of modellers who wants to build a kit inside out, to maybe show off a full interior, and do it in an unparalleled detail, then this kit is for you.

Two things that I noted and especially appreciated. All of the parts for the front engine just say - they are mostly on one sprue. Same with the cockpit, all of the sub-assemblies are so easily put together and made as you are not doing the "dance of 1000 sprues" to get to them.

The moulding also must be noted. Smart choices to keep flaws out of sight as much as possible, and a general improvement I have noted since the first ZM kit I owned has impressed me. The lack of flash and sharp detail of the parts here is ad good as any other model makers in the market right now.

The care, effort and dare I say a word that is not often used in modelling circles about manufacturers "passion" for the end product is all in front of you in this review. The care that has gone into the production from the concept of recreating a machine rather than a model, the trip to measure the aircraft in such detail, the instruction manual that calls back to yesteryear and explains everything as it all goes together.

There is a lot of love and a lot of heart that has gone into the making of this kit, and yes it is OK to use the word "passion" when talking about such a project as this model.

Adam Norenberg

Thanks to the folks at Zoukei-Mura for sending this kit to us to review. You can get it now from the Volks and Volks USA websites and several other select suppliers, see where to get yours on the ZM website.